When completing ASME code calculations involving cylindrical components it is possible during examinations you will be required to know how to determine the thickness of a blank unstayed full-hemispherical head. I recommend before working on questions involving hemispherical head questions you read over and complete the practice questions regarding How To: Determine The Thickness Of A Blank Unstayed Dished Head.

Throughout this post I will provide and formula(s) and where to find them. Describe the variables used in the formula(s). Provide insight or sketches to help describe any of the code requirements I have found particularly important for understanding blank unstayed full-hemispherical head questions. Then provide some completed practice questions to help reinforce the material before wrapping everything up with a summary of the topic.

All reference page numbers are from the 2007 ASME Boiler & Pressure Vessel Code

Formula

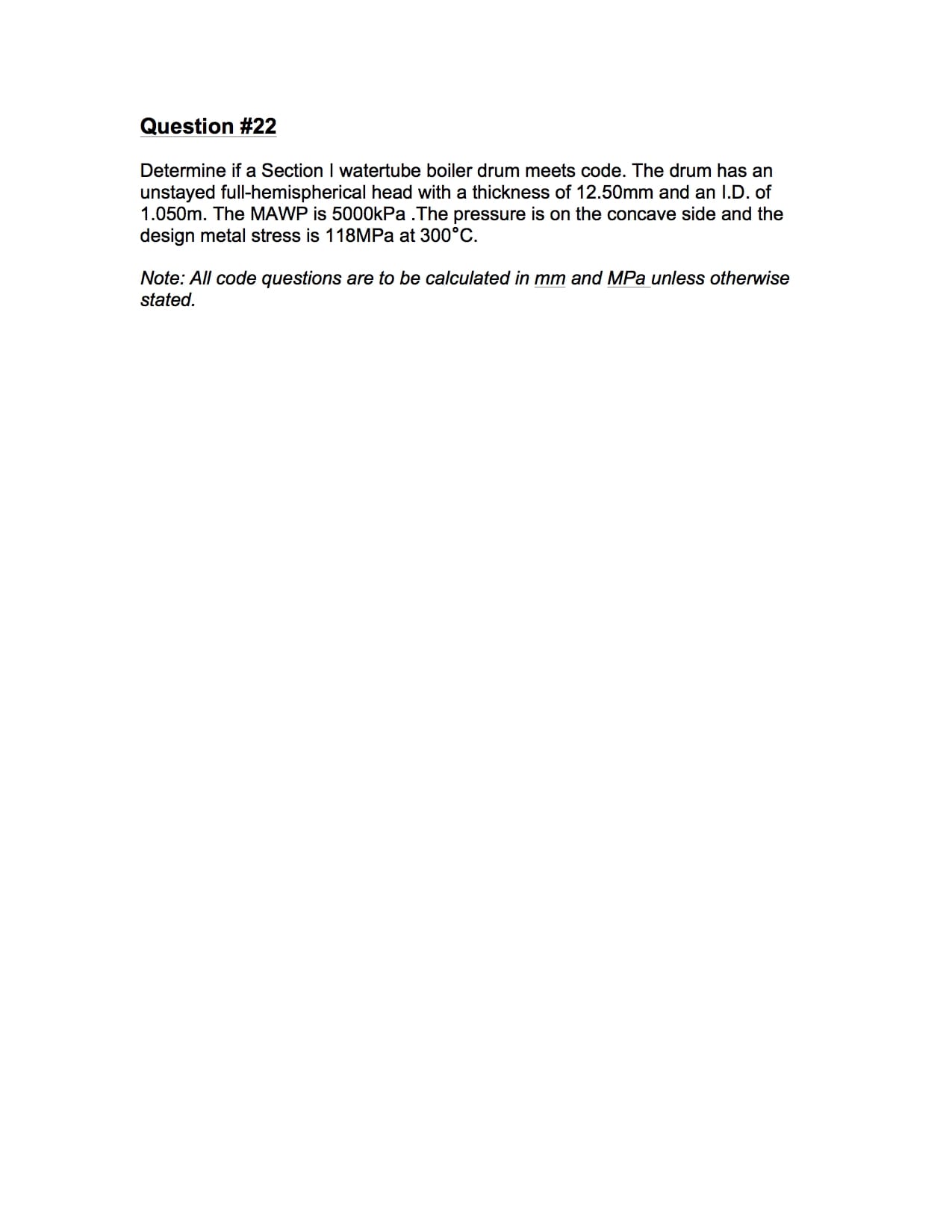

The formula for how to determine the thickness of a blank unstayed full-hemispherical head with pressure on the concave side is under PG-29.11 page 14.

Minimum Thickness Formula

![]()

The above equation should not be used when the required thickness of the head given by the above formula exceeds 35.6% of the inside radius, and instead these following two equations should be used:

Where

Formula Variables

The formula variables above are explained on page 14 and are as follows:

L = Is the radius to which the head was formed, measures on the concave side of the head

P = Maximum allowable working pressure

S = Maximum allowable working stress, using values given in Table 1A of Section II, Part D

t = Minimum thickness of head

w = weld joint strength reduction factor per PG-26

Important Full-Hemispherical Head Code Requirements

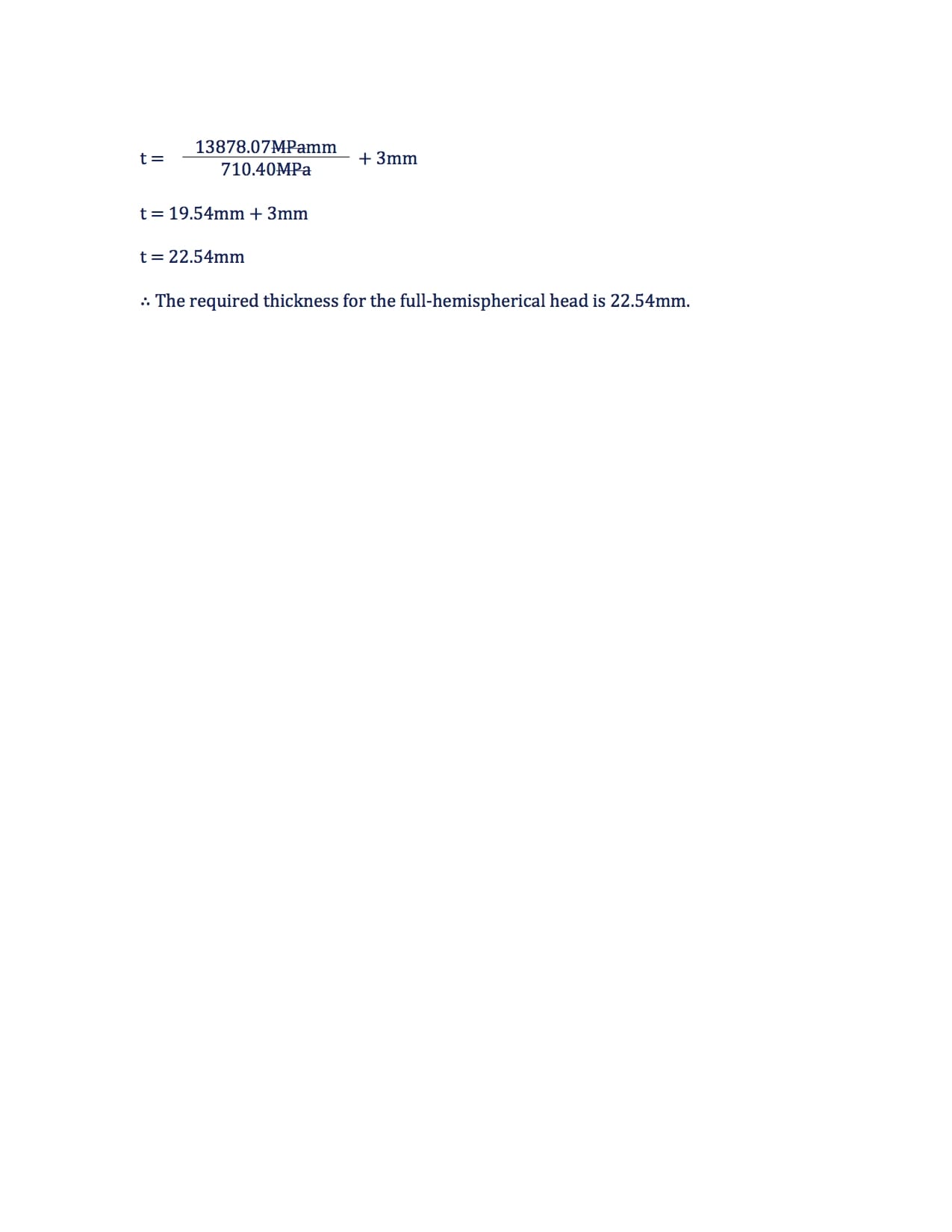

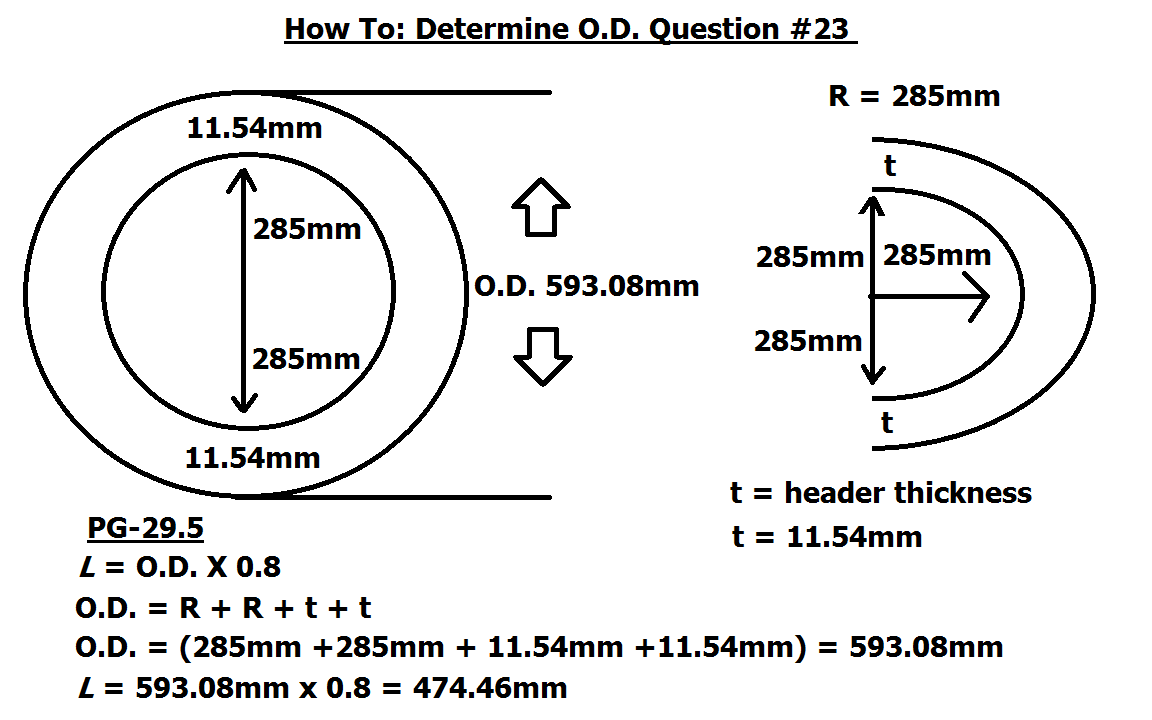

PG-29.12 page 14 – If a flanged-in manhole that meets the code requirements is placed in a full-hemispherical head, the thickness of the head shall be the same as for a head dished to a segment of a sphere ( see PG-29.1 and PG -29.5), with a dish radius equal to eight tenths the diameter of the shell and with the added thickness for the manhole as specified in PG-29.3.

[table id=1 /]

How To: Determine The Thickness Of A Blank Unstayed Full-Hemispherical Head Questions

Note: All code questions are to be calculated in (mm) and (MPa) unless otherwise stated. Convert accordingly and properly before the calculation.

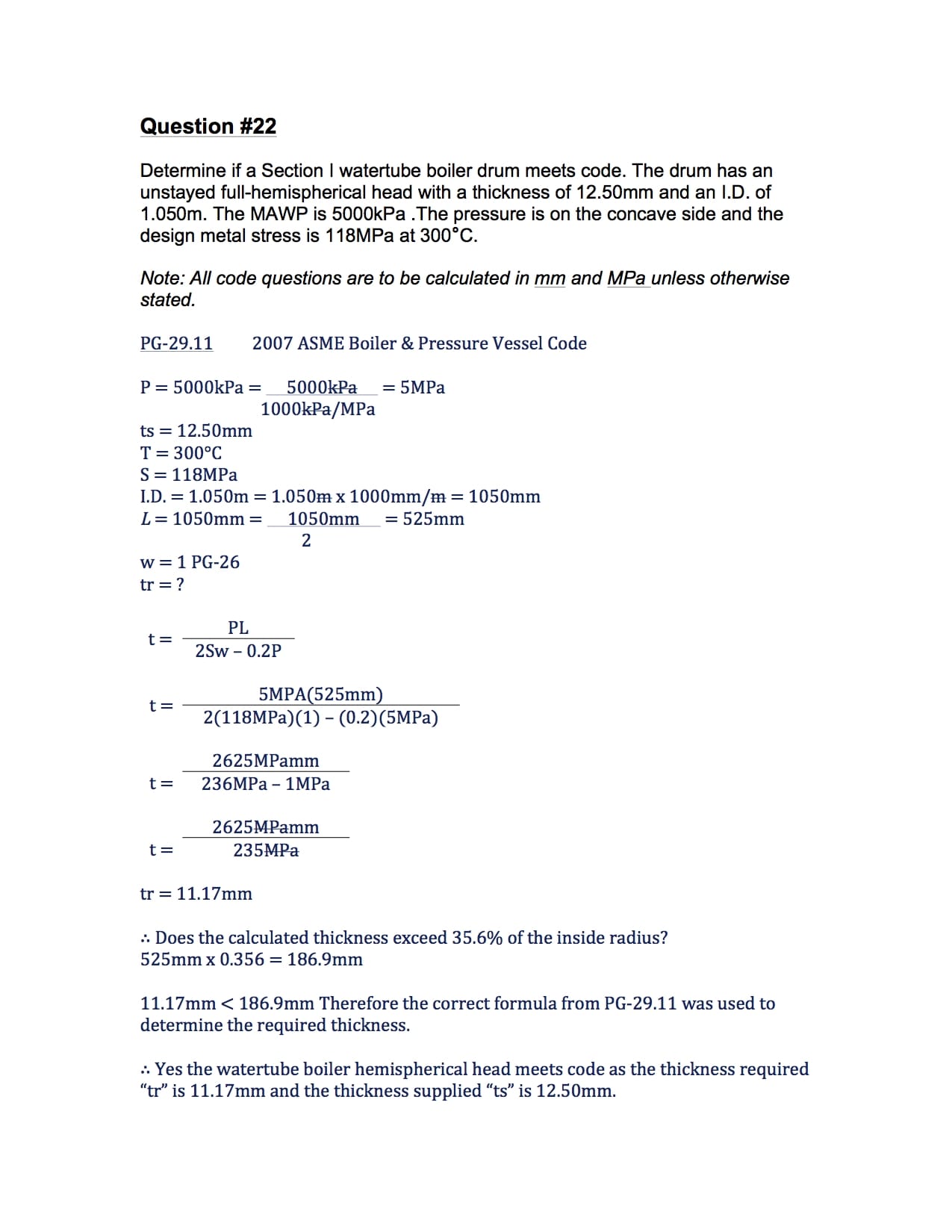

Question #22

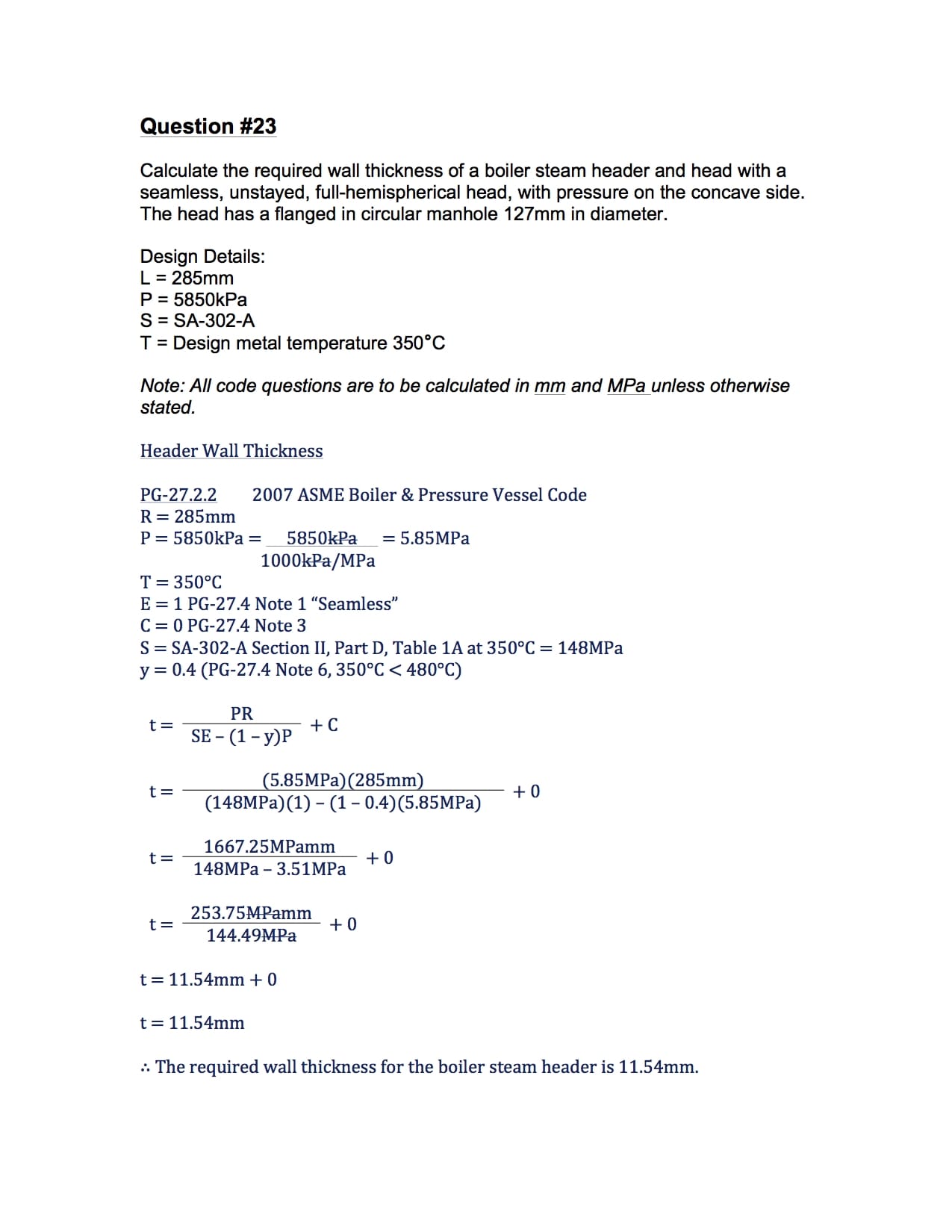

Question #23

Summary: Determine The Thickness Of A Blank Unstayed Full-Hemispherical Head

Let me hear your thoughts about this post and if the practice questions were helpful. If you want to be alerted of the latest posts follow us on Twitter as I tweet as soon as a new post is posted.

Thanks,

Power Engineering 101