Today we will be reviewing calculations involving How To: Determine Corrugated Furnace Calculations. We will review the formula(s) to determine the required thickness and the maximum allowable working pressure. Then define the different variables in each of the formulas and review numerous practice questions to reinforce the material covered.

All referenced page numbers are from the 2007 ASME Boiler & Pressure Vessel Code

Formula

PFT-18.1 page 94 The maximum allowable working pressure on corrugated furnaces, such as the Leeds suspension bulb, Morison, Fox, Purves, or Brown, having plain portions at the ends not exceeding 9 in. (230mm) in length (except flues especially provided for), when new and practically circular, shall be computed as follows:

Maximum Allowable Working Pressure Formula

Minimum Thickness Formula

The MAWP formula above can be transposed to determine the required minimum thickness formula for corrugated furnace calculations

The above formula is not provided in the 2007 ASME Boiler & Pressure Vessel Code

Formula Variables

C = 17,300 (119), a constant for Leeds furnaces, when corrugations are not more than 8 in. (200mm) from center to center and not less than 2 1/4 in. (57 mm) deep

= 15,600 (108), a constant for Morison furnaces, when corrugations are not more than 8 in. (200mm) from center to center and not less than 1 1/4in. (32mm) deep, and the radius of the outer corrugation r, is not more than one-half of the radius of the suspension curve R (see Fig. PFT-18.1)

= 14,000 (97), a constant for Fox furnaces, when corrugations are not more than 8 in. (200mm) from center to center and not less than 1 1/2. (38mm) deep

= 14,000 (97), a constant for Purves furnaces, when rib projections are not more than 9 in. (230mm) from center to center and not less than 1 3/8 in. (35mm) deep

= 14,000 (97), a constant for Brown furnaces, when corrugations are not more than 9 in. (230mm) from center to center and not less than 1 5/8 in. (41mm) deep

D = mean diameter

P = maximum allowable working pressure

t = thickness, not less than 5/16 in. (8mm) for Leeds, Morison, Fox, and Brown, and not less than 7/16 in. (11mm) for Purves furnaces.

When calculating the mean diameter of the Morison furnace, the least inside diameter plus 2 in. (50mm) may be taken as the mean diameter.

[table id=1 /]

How To: Determine Corrugated Furnace Calculations Questions

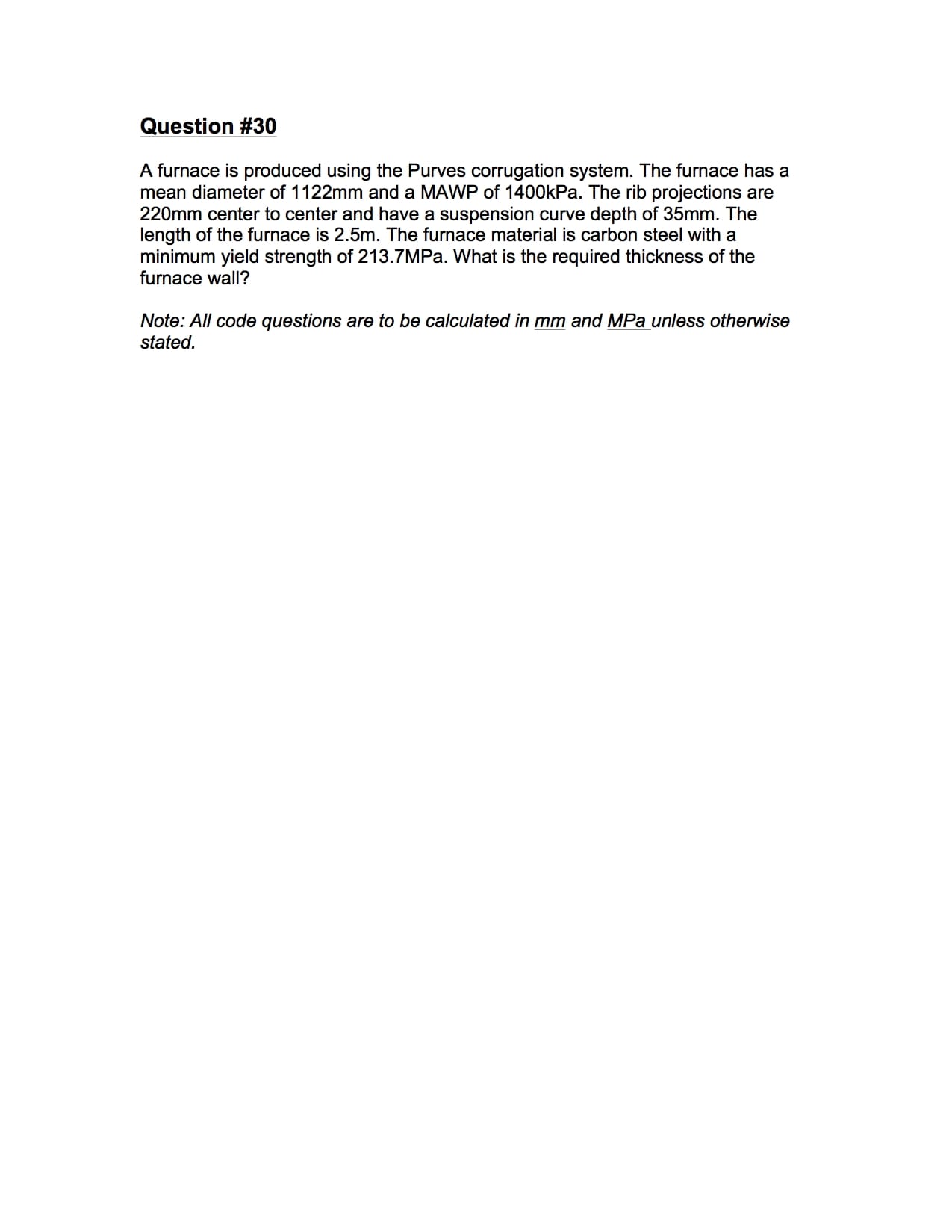

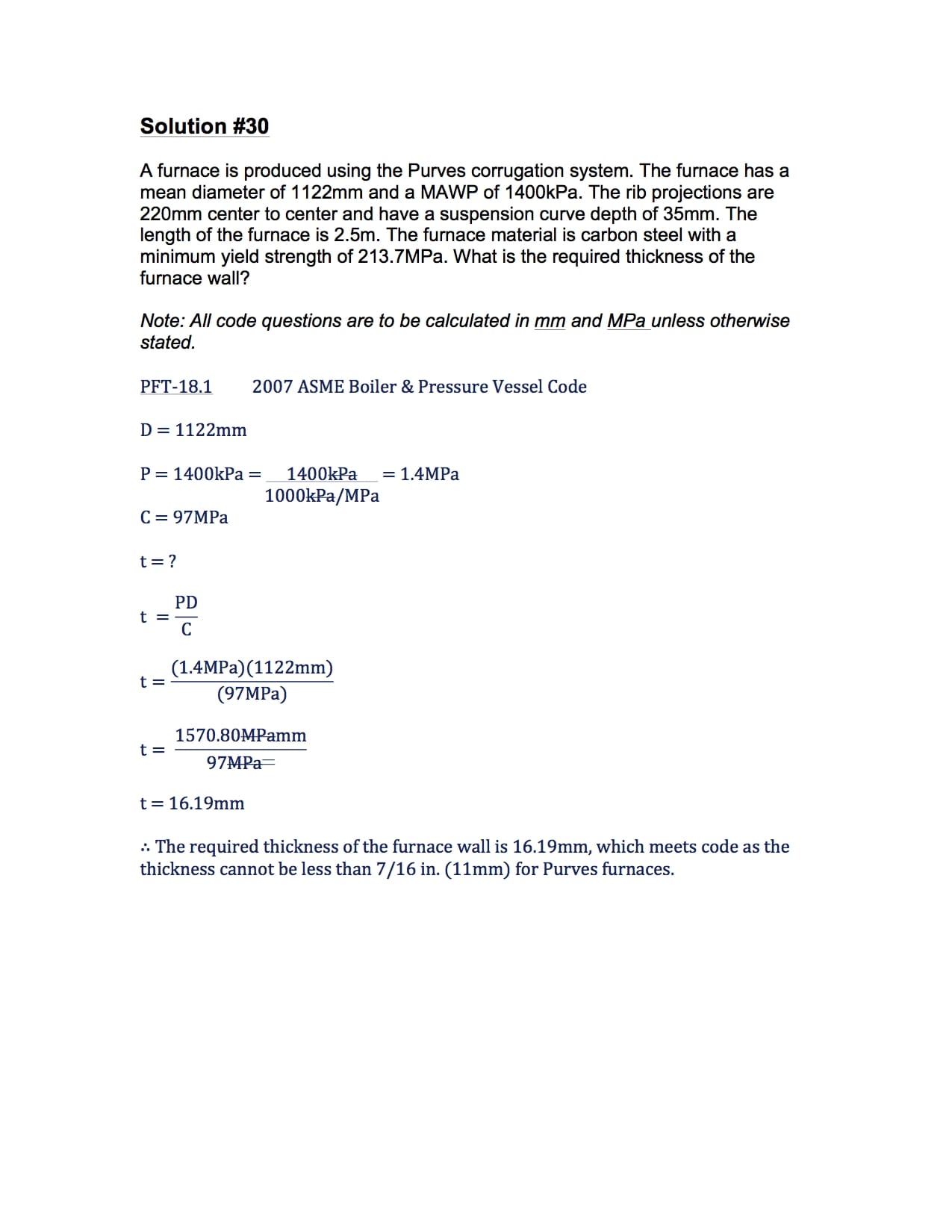

Question #30

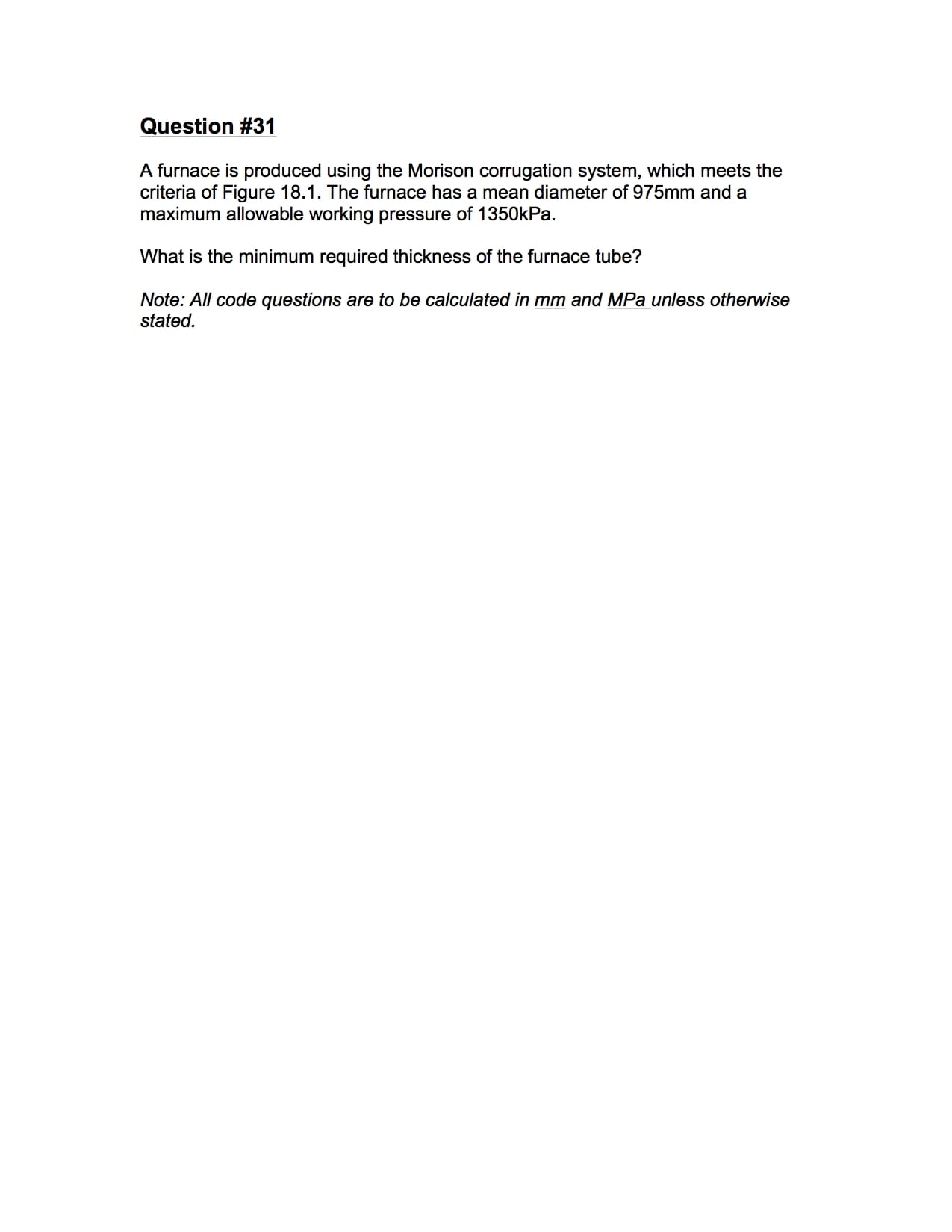

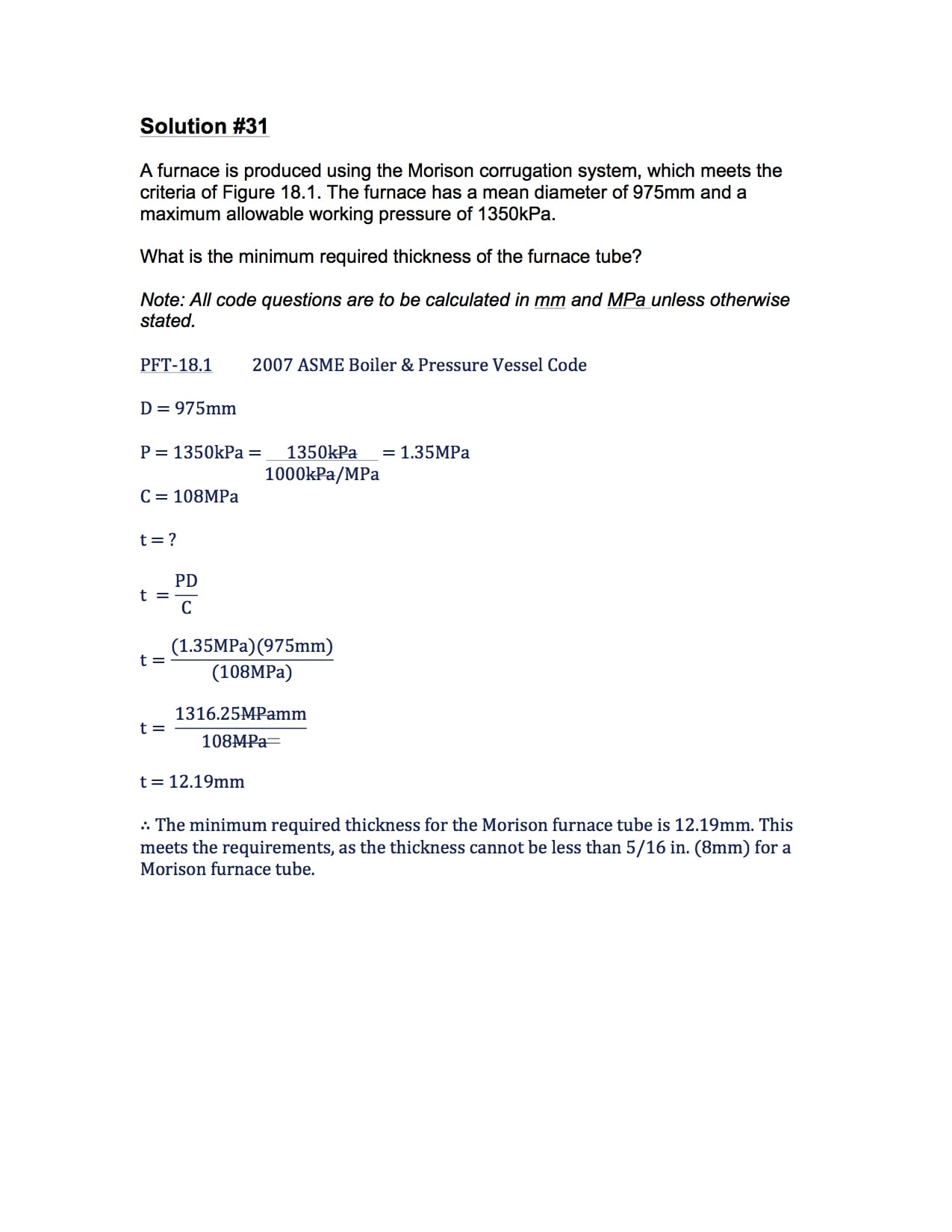

Question #31

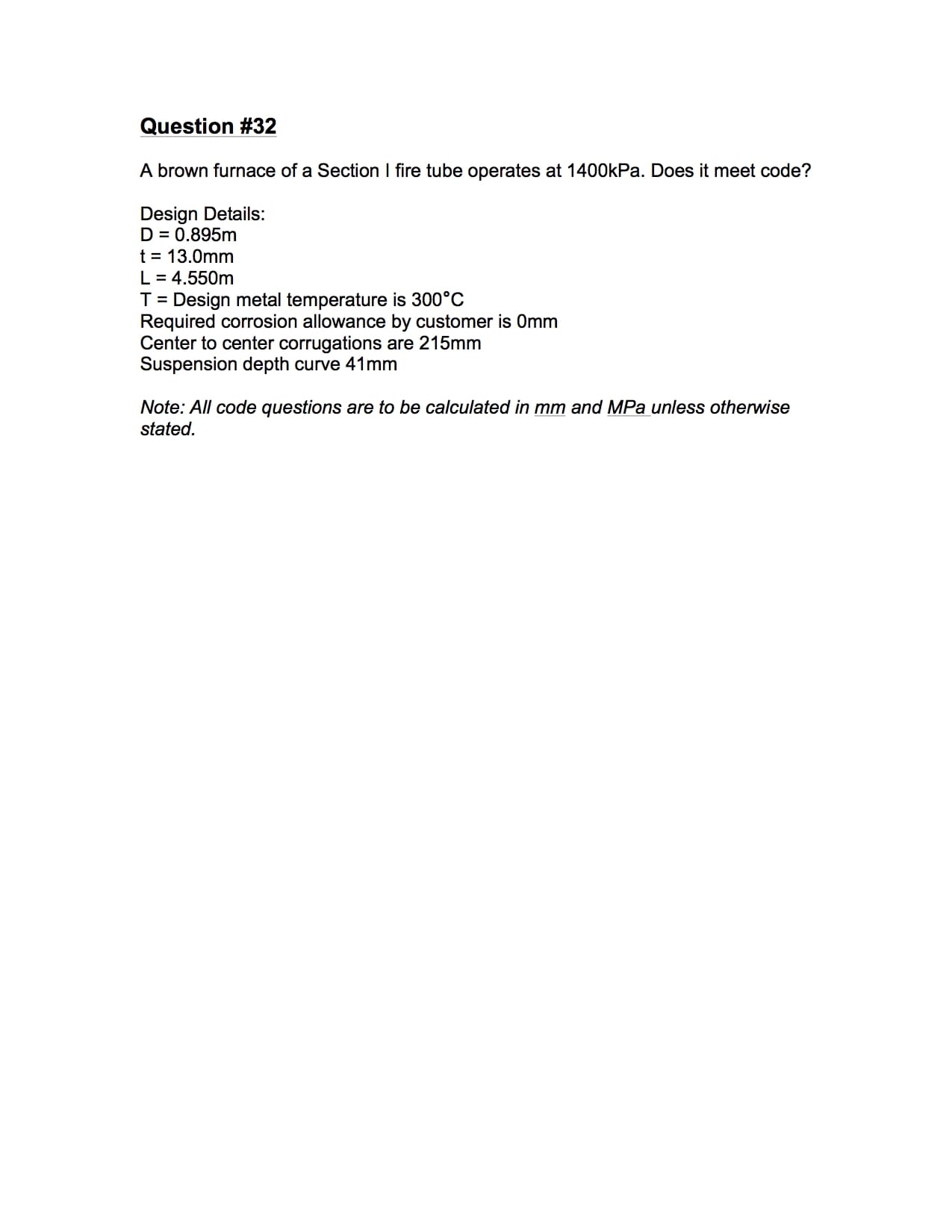

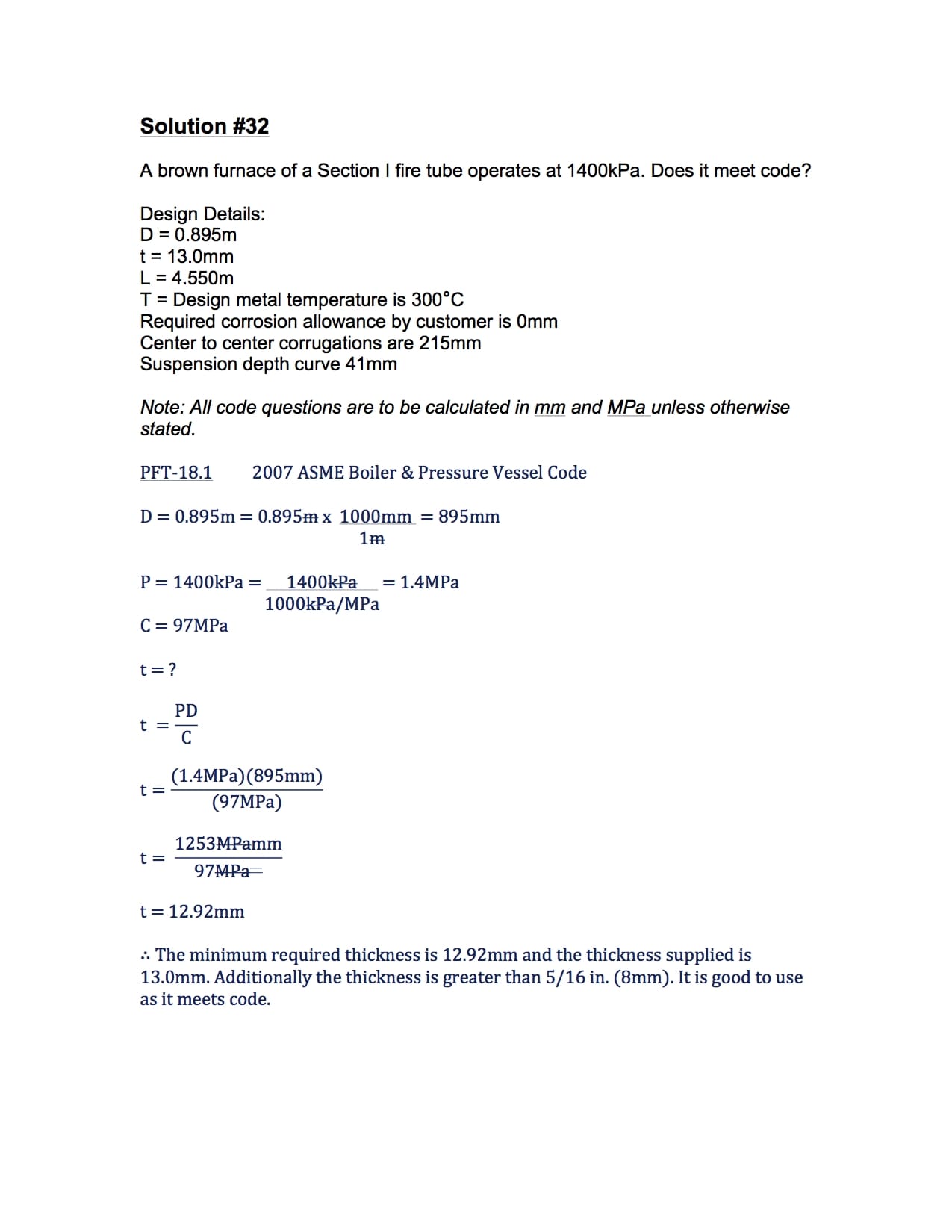

Question #32

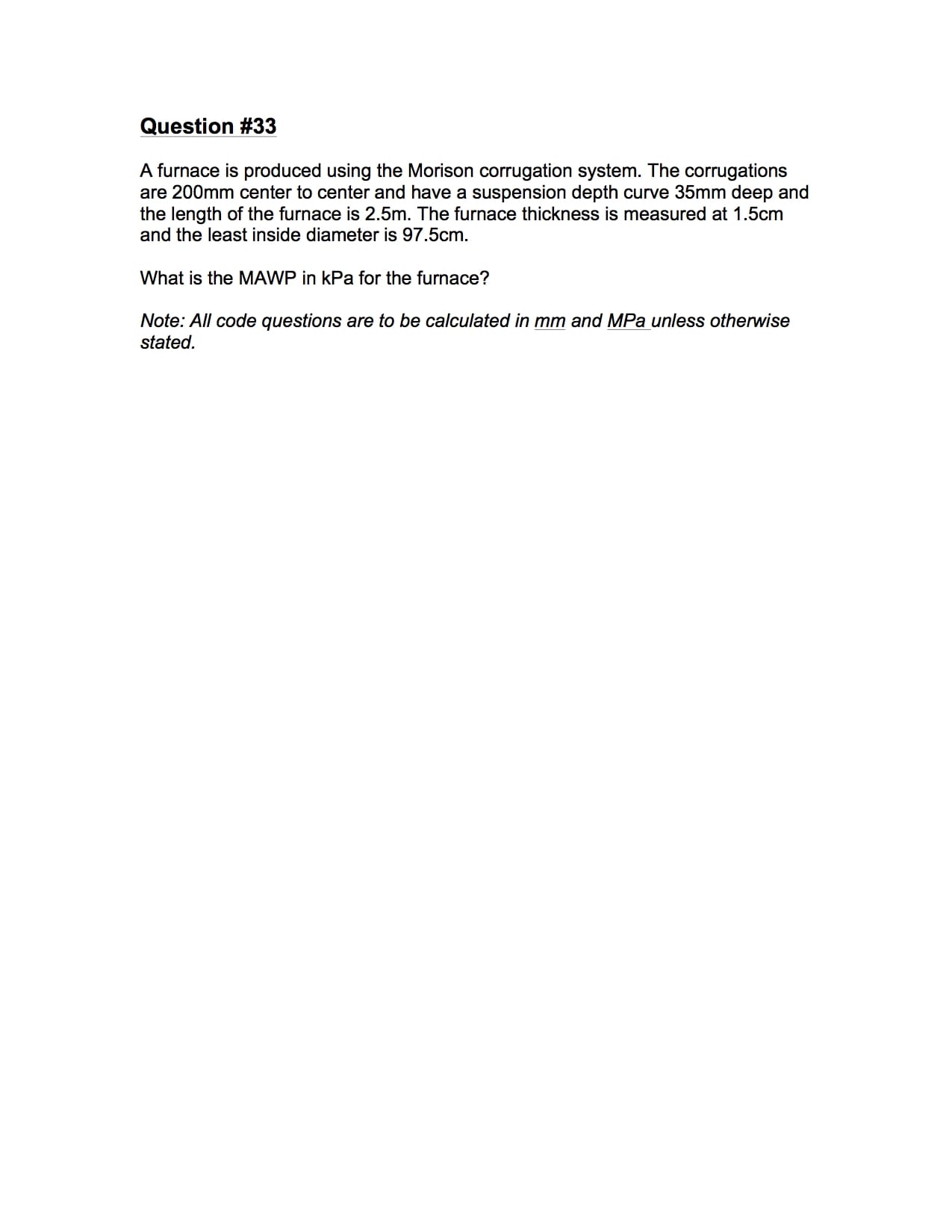

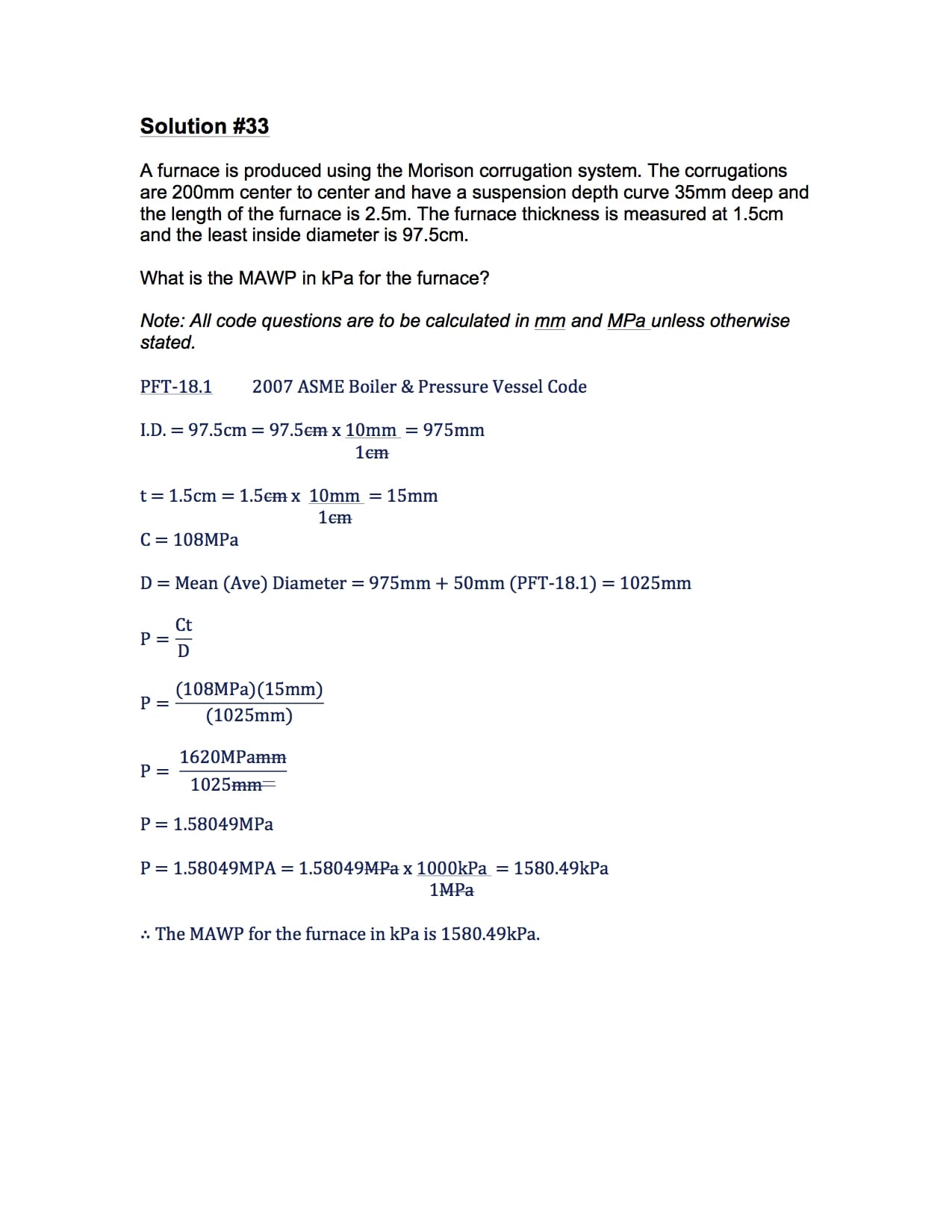

Question #33

Summary

While completing corrugated furnace questions make sure that the calculated thickness is not less than 5/16 in. (8mm) for Leeds, Morison, Fox, and Brown, and 7/16 in. (11mm) for Purves furnaces.

Good luck completing how to: determine corrugated furnace calculations!

Power Engineering 101